Time hardening procedure

For the damage models used in the incremental-recursive process the parameters on the right hand side of the equations may change from increment to increment. In the model for fatigue damage of asphalt layers, for example, the strain, the modulus and the temperature may change from increment to increment. The first step in the process is, therefore, to calculate the “effective” number of load applications that would have been required, with the present parameters, to produce the condition at the beginning of the increment. In the second step the new condition, at the end of the increment, is calculated for the “effective” number of load applications plus the number of applications during the increment. This must be repeated for each load and load position during the increment.

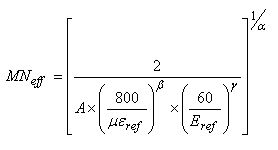

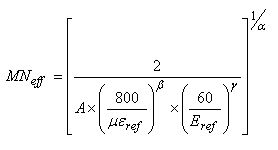

The method may be illustrated by an example using the equation for permanent deformation of unbound layers. If for example the permanent deformation of the subgrade was 2 mm at the start of the increment, the vertical strain calculated for the first wheel load at the first position was 800 microstrain, and the modulus of the subgrade was 60 MPa. Then the effective number of load applications at the start of the increment (in millions) may be found from:

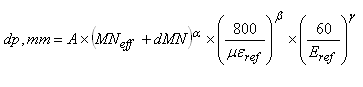

If the number of repetitions, in millions, of this load, at this position, is dMN during the increment, then the permanent deformation after these loads have been applied would be:

The process must be repeated recursively, using the output from each calculation as input to the next, for all loads at each position, before proceeding to the next time increment. The process is also illustrated in the figure below: